|

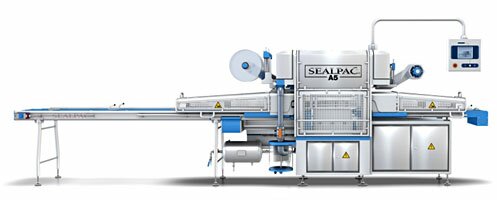

A5 |

The SEALPAC A5 has so much to offer with its compact design and complete performance. We bring you the professional approach, crucial in industrial processing even at entry-level. Fully automated, this unit combines all the benefits of larger models with its compact and space-saving format.

The tooling exchange system from both sides, flexible tray heights, in-house manufactured low-maintenance gas valve, servo controlled film transport for left and right hand operation and tailor-made tray transportation systems make the SEALPAC A5 a flexible solution for individual applications, whether cold or hot fill, MAP (Modified Atmosphere Packaging) or TraySkin® packaging.

Accessories & auxiliary equipment

Benefits

- Servo controlled film transport

- Various in-feed systems for all types of trays

- Pneumatic tooling quick exchange system; no hand tools required

- Machine can be operated on both sides

- Separate channels for vacuum and gas

- Touch screen panel with 50 programmes

- Secure tray guidance in all sequential stages

- Trouble-free integration in existing production lines

- Interface for external communication

- High sealing pressure

- Proven SEALPAC InsideCut sealing

- Wash-down stainless steel frames

- Self-draining hygienic construction

- IP 65 rating

Technical details

- Output: up to 70 trays/minute

- Capacity: up to maximum 15 cycles/minute

- Machine weight: 1,600 kg

- Air pressure: min. 6 bar

- Connection values: 3 x 400/230V+N+E - max. 8 kW